410 Microlight tilsettes WEST SYSTEM epoxy for å lage en sparkelblanding med ekstremt lav vekt. Gir en epoxy-sparkel som er lett å forme og lett å pusse. Dersom sparkelmassen skal overmales bør den først forsegles med et strøk WEST SYSTEM epoxy uten fyllstoff. Tilsettes i forholdet 7-16 % av blandingens totale vekt.

Farge: Beige.

410 Microlight® Filler

WEST SYSTEM® 410 Microlight is made of tiny hollow plastic spheres with a bonding agent to allow them to gently cling together

What is it? WEST SYSTEM® 410 Microlight is a filler designed to create a lightweight and easily worked fairing compound when added to a mix of epoxy. It consists of tiny thermoplastic hollow spheres, which makes it very easy to sand once the mix has hardened. Although light sand in colour when in the pot, it darkens to a shade of tan when cured. Whilst it is perfect for a wide range of final fairing applications, 410 Microlight should not be used where it might encounter high temperatures, so this includes being used under dark paints. (There are superior strength-to-weight alternatives in the WEST SYSTEM range, such as 407 Low Density Filler.)

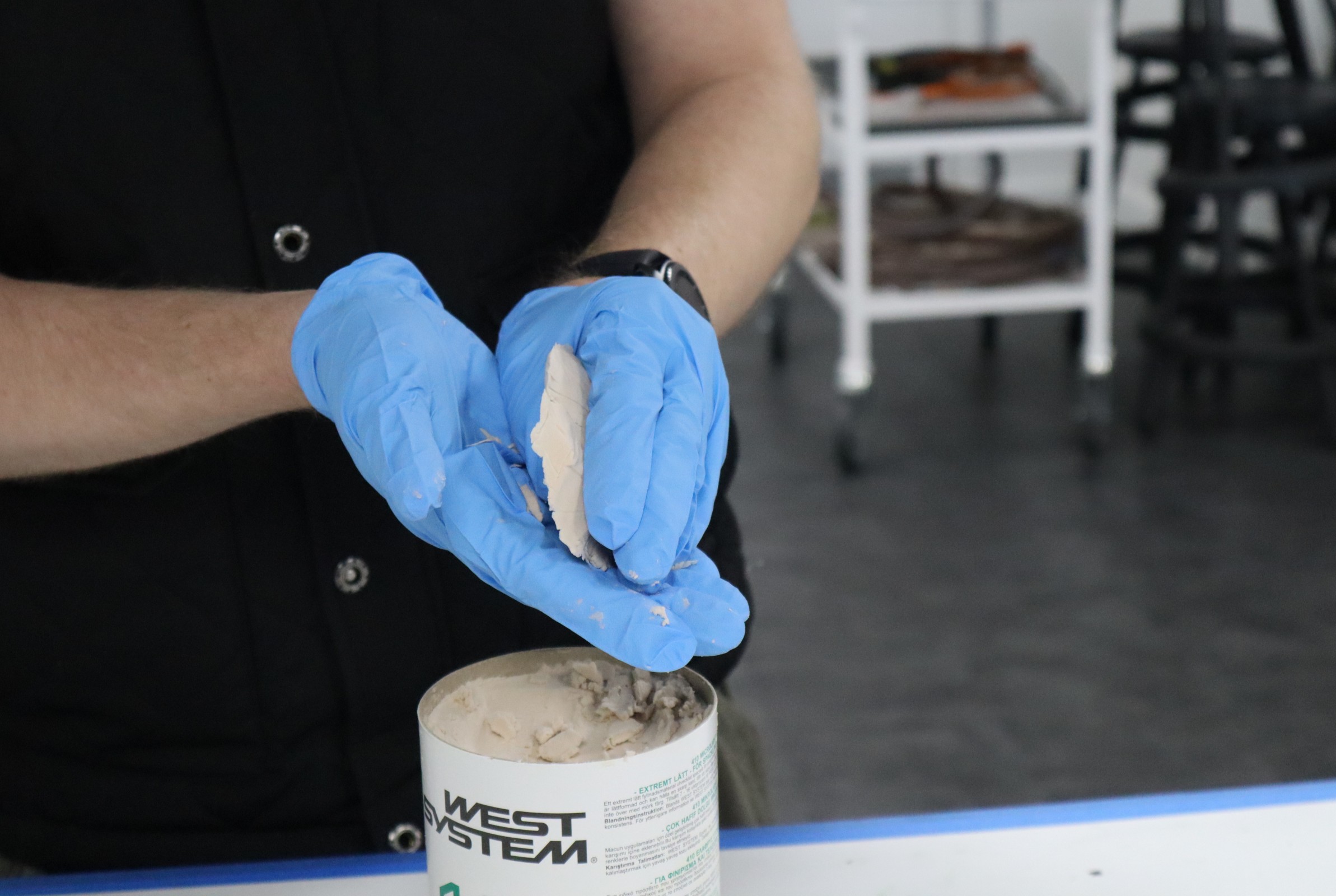

The bonding agent allows the filler to form sharp edges, ideal for merging surfaces

Used for? Because of its very low density, WEST SYSTEM 410 Microlight is ideal for fairing large areas and can also be used in more tricky jobs such as vertical surfaces or even overhead. The bonding agent allows the filler to be moulded into a sharp edge, so you can easily feather one surface into another.

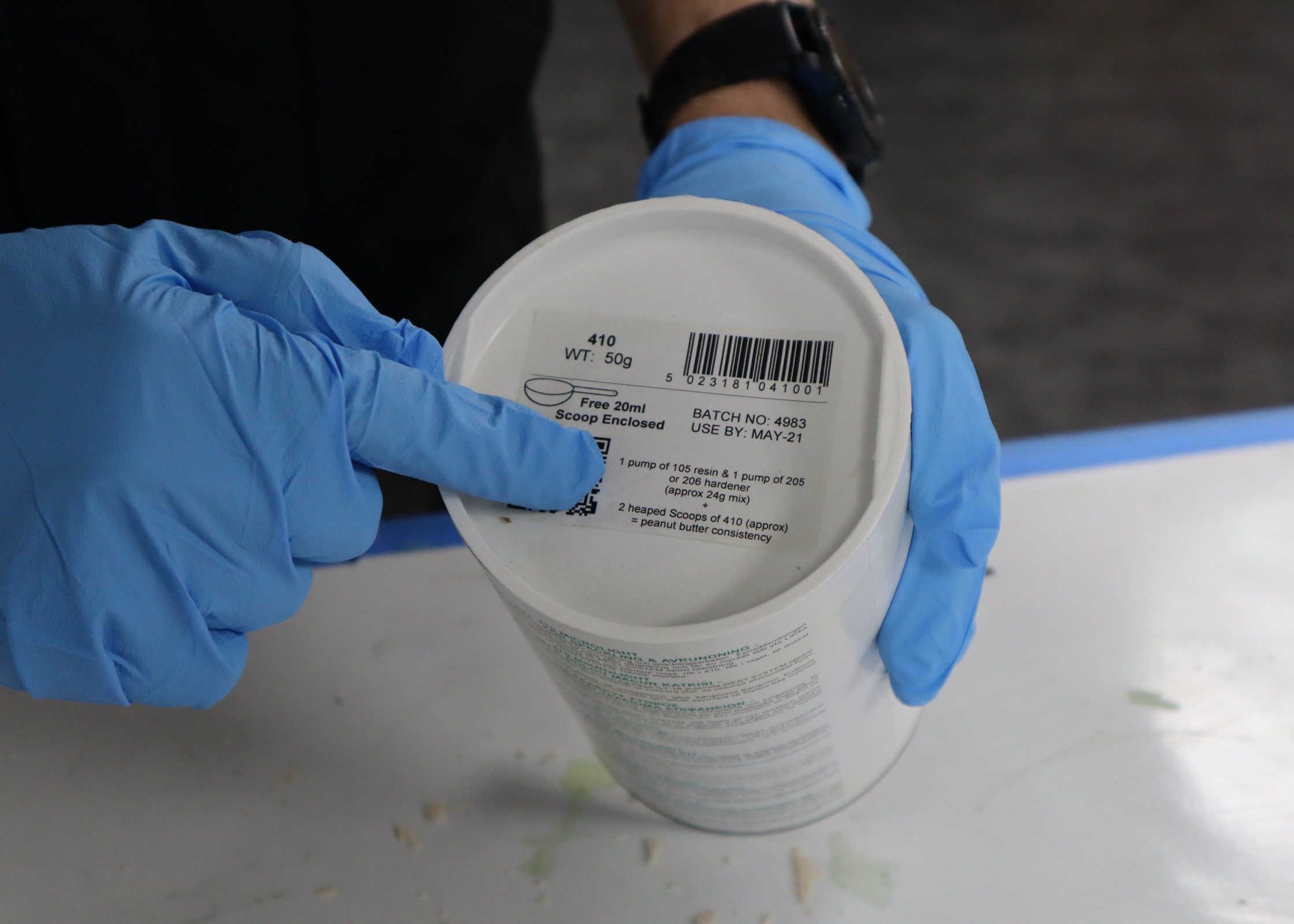

Basic mixing ratios by volume are found on the top of all WEST SYSTEM additives. These are the directions for 410 Microlight.

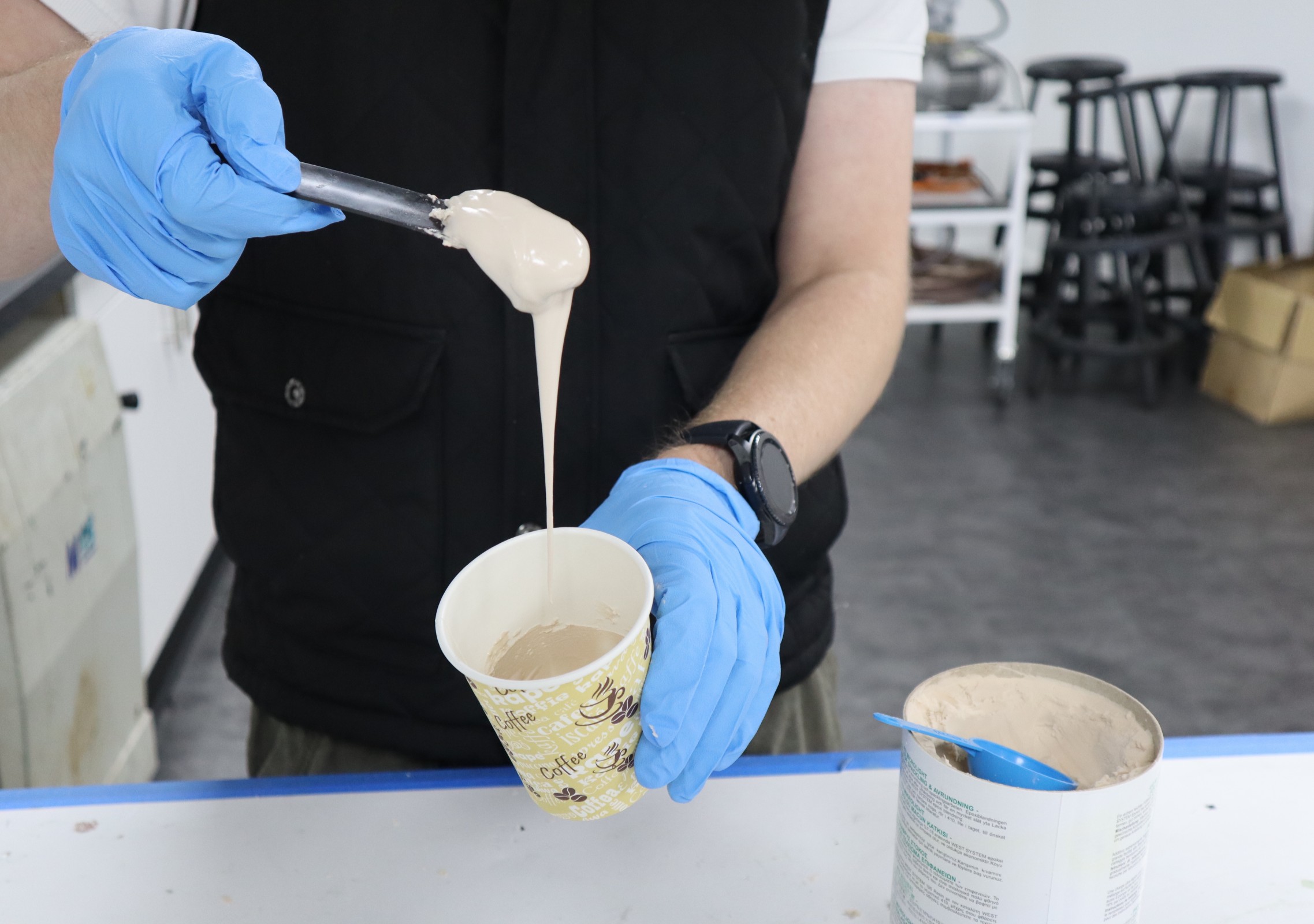

Mixing ratio? WEST SYSTEM 410 Microlight is easily blended into an epoxy mix at a ratio of between 7% and 16% by weight, depending on the consistency you require. To measure by volume, the scoop supplied with the pot should be used. Two heaped scoops will give a peanut butter consistency once thoroughly mixed with the epoxy. Once the filler is added to the epoxy, it is recommended to stir for at least one minute to ensure full wetting out of the filler.

Hamish’s tips for perfect results.

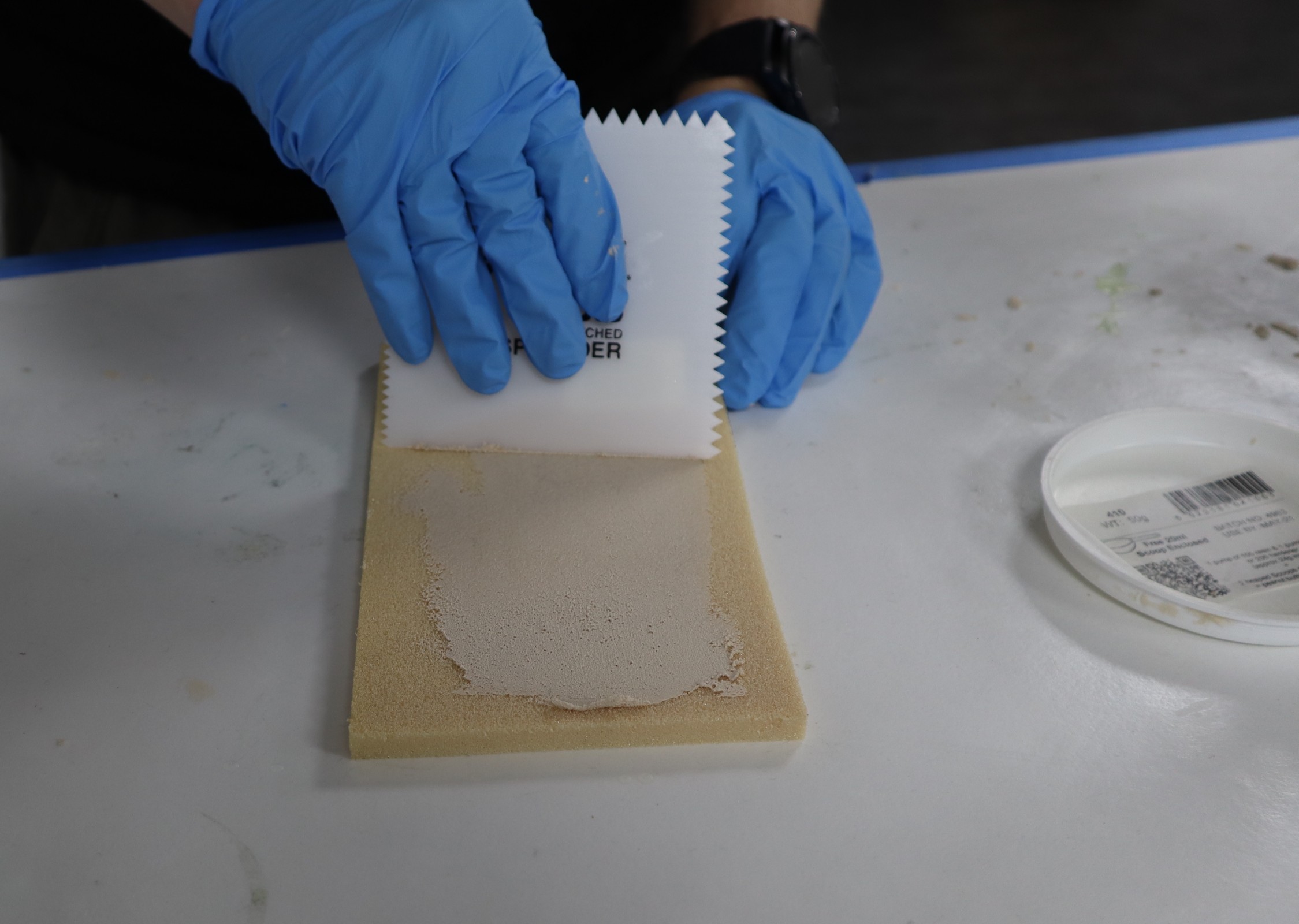

“Microlight is an ideal low-density fairing material and we use it on our WEST SYSTEM courses for novices to try, as it is so easy to mix and apply. The students seen here are using 105 Epoxy Resin with 205 (fast) Hardener mixed with 410 Microlight to fair a piece of reinforcing cloth that has been bonded to a sheet of plywood. They soon discover that the blend is very forgiving and will create a smooth surface that is easy to sand. The reduced effort needed to abrade the cured surface back is important if preparing a large hull for primer and undercoat.”

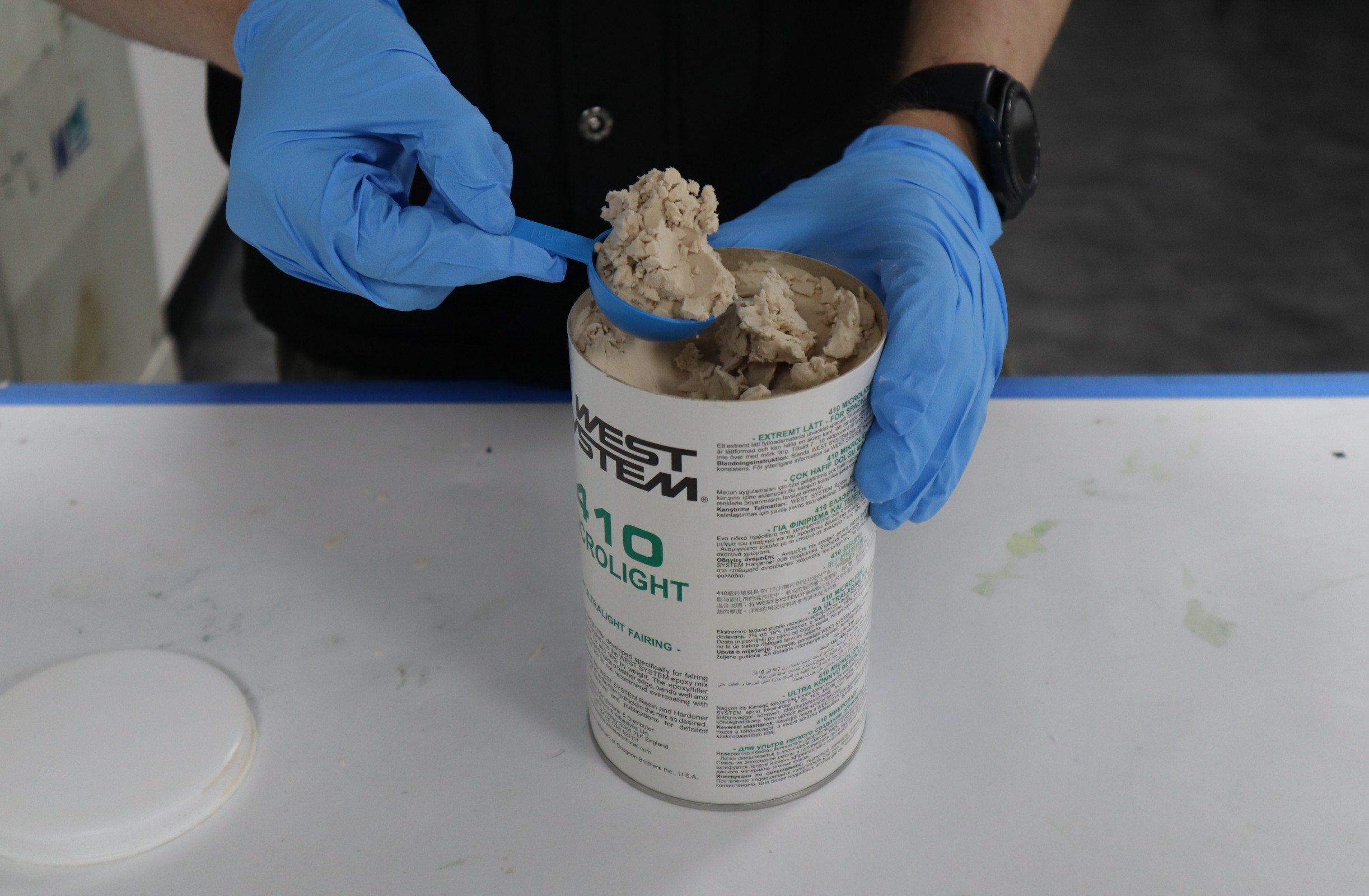

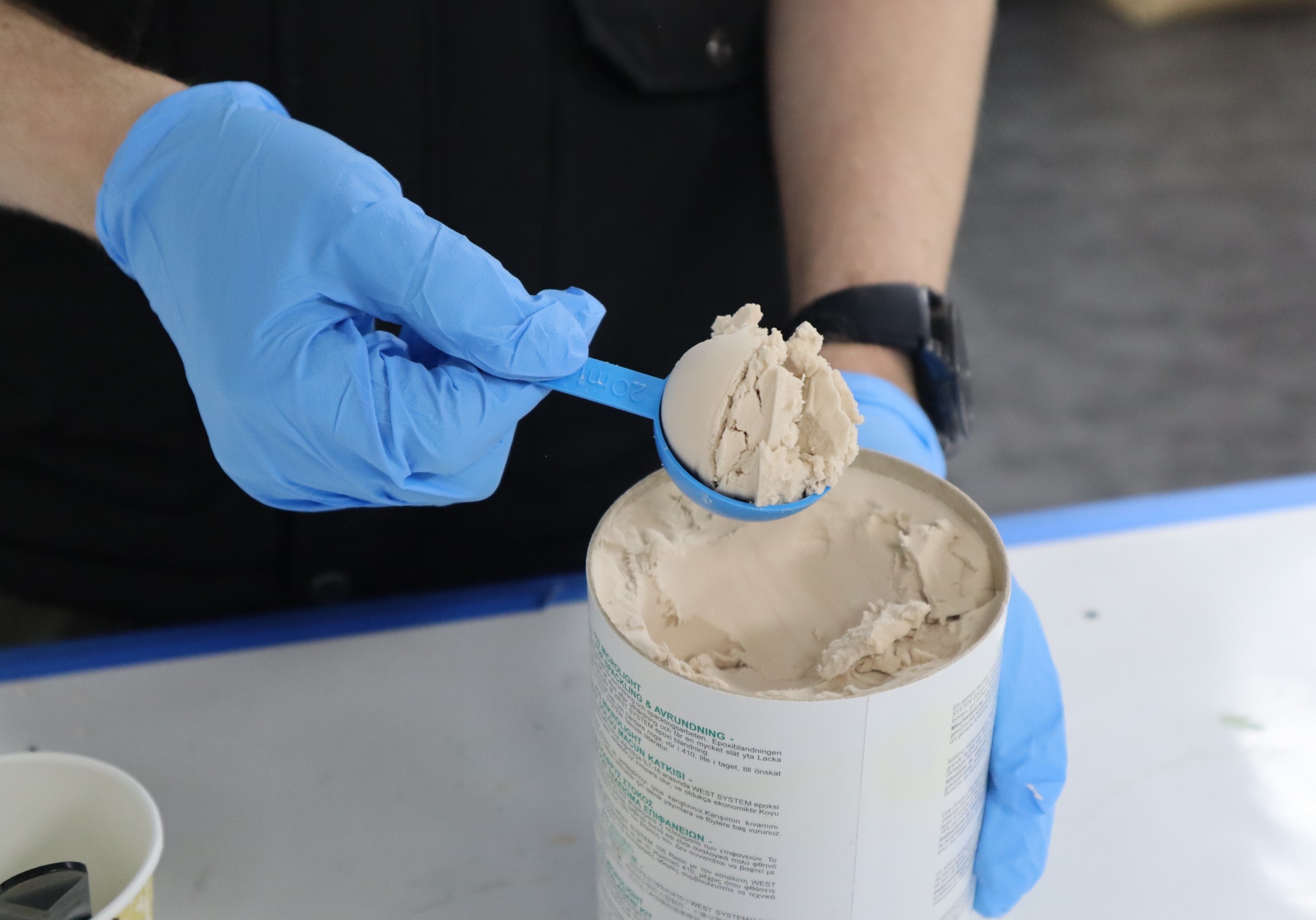

Scoop deep: “It is deceptive how much filler you will need. The scoop should be heaped up like this to ensure you have enough material. Two of these to every pump of both resin and hardener is the right mix, but you can err on less if using it for the first time and top up until happy you have the right mix.”

Lose the gloss: “If the mix still looks glossy, like this, then it probably needs a bit more stirring, as all the ‘wet’ epoxy has yet to mix fully with the additive. You are looking to achieve a flat matt texture. This is ‘mayonnaise’ consistency, ideal for spreading out with a squeegee (flexible plastic blade) over a large flat surface. The epoxy/410 Microlight mix sinks easily into the weave of reinforcement cloth or the pores of a piece of foam, creating a smooth surface that is ideal for further coating.”

Adjust the mix:

“If you intend to use epoxy/410 Microlight blend for vertical or overhead applications, then it needs to be thicker so go for the peanut butter consistency, like this.”

Apply with a squeegee:

“For vertical and overhead surfaces, this thicker mix will be easy to apply using the flat edge of your squeegee. The fact it is so lightweight makes it more resistant to gravity, so it tends to stay where you put it and not drop into your hair.”

Remember, it’s built for looks, not strength:

“Don’t be tempted to use 410 Microlight for filleting or other load bearing jobs. There are much better additives for that, such as the High-density range (402 Mixed Glass Fibre Blend through to 406 Colloidal Silica). As the brand name suggests, this very low-density Microlight blend is intended to give a smooth surface where the benefits are decorative rather than structural. The strength itself will come from the substrate underneath.”